Test Solution

LCD panel manufacturing is divided into an Array, the Cell, such as the Module is installed in a series of technological process each process will produce some process defects, such as dim bright flash point of these defects such as broken window will cause local show bad, but we can through the laser line cut, welding, darkening method to repair or fade in the actual production in about 5% of the point defects, with a laser repair or fade out after, can promote panel product yield, and reduce the production cost of the panel companies.

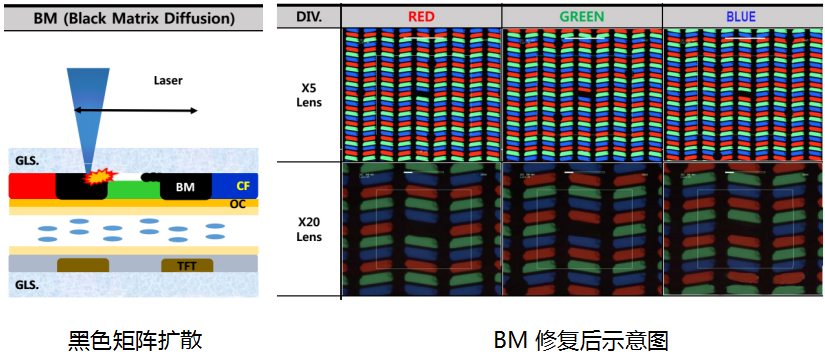

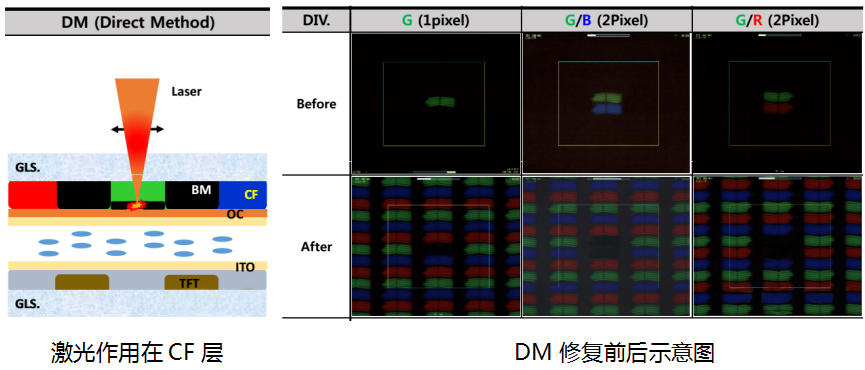

Point defect is the most common problem of the LCD panel, the LCD panel manufacturing process, including dust organic metal foreign bodies will be adsorption to the LCD panel when the utensil was to close to the color filter area, corresponding to the color filter pixels emit a much brighter than the rest of the normal pixel light, which is referred to as a pixel point Semishare joint American ESI to become the industry's first flexscan technology being developed for the pixel window, BM repair and DM repair.

BM repair laser was mainly used in need of repair of the pixel color film and glass substrate is formed between clearance, and then use laser to the pixels around the graining of the black matrix processing, and will produce the black particles into the gap, repeating the process until the black particles is covered on the pixel, finally complete the repair.

DM repair is to carbonize CF or ITO on transparent electrode of pixel bright spot by directly acting on CF(color filter) or ITO with high energy ultra-fast laser, so as to achieve the purpose of darkening the bright spot.

The SEMISHARE FlexScan BM&DM laser repair equipment is suitable for the small size of the LCD panel window in the large defect repair with fast, uniform, and yield was significantly higher than that of traditional BM, the characteristics of the DM technology, have CCD automatic detection function, can automatically find and locate precisely to bad point, after the completion of the repair process, automatically complex sentence selected automatically according to the results of the complex sentence or repair under the expected, the entire journey without too much manual intervention, which can ensure the quality of repair, also can greatly improve repair efficiency.

SEMISHARE Flexscan technology solves the defects in panel manufacturing process, breaks the technical boundary of the industry, and occupies a leading position in the industry, providing panel enterprises with more comprehensive solutions, helping them to improve product yield and reduce production costs.