Test Solution

English name LASER Light Amplification by Stimulated Emission of Radiation (LASER), mean Light Amplification by Stimulated Radiation LASER English full name is fully expressed the main manufacturing LASER process atoms Stimulated Radiation Light, and therefore LASER: after absorbing energy from low energy level of electrons within atoms transition to high level, and then fell back from high level to low level, the release of energy in the form of photons releasedBe tempted (inspire) of photon beam (laser), photon optical properties of these highly consistent so laser compared to good monochromaticity directional light source, the brightness higher laser is known as the fastest knife most accurate feet the brightest light using laser generated by high temperature, will be gasification and melting TFT poor internal defects, to reduce or eliminate, the dot defet and line defect in laser repair grade to patch for shipment.It is called panel laser repair technology.

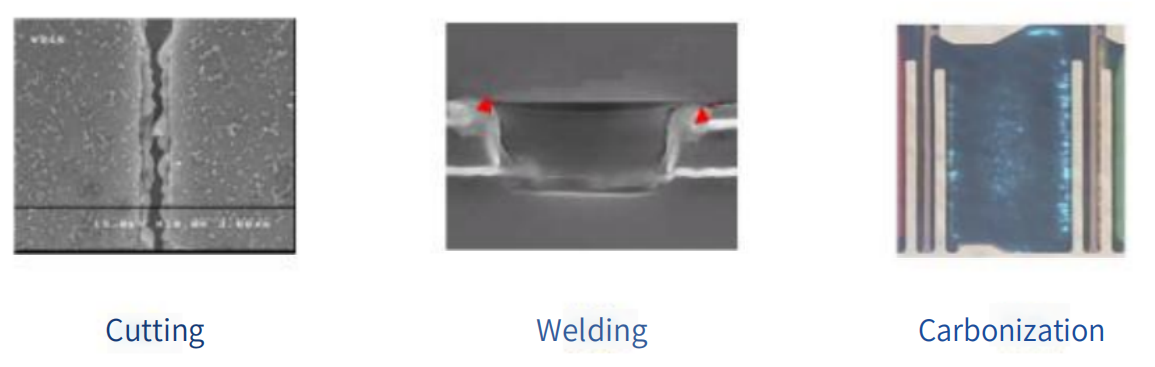

Common laser repair techniques are as follows:

Cutting: the use of laser cutting to solve the short-circuit and the role of isolation circuit.

Welding: the main purpose is to darken the bright spot and solve the bad conduction.

Carbonization:High frequency laser is used to carbonize CF photoresist to achieve the purpose of bright spot darkening.

Coverage: BM was granulated with laser and promoted to cover other luminescent areas to achieve the purpose of dimming bright spots.

Deposition: Laser chemical vapor deposition (LCVD) is used to repair broken wires and solve the problem of open circuit.

| RMS STABILITY(1ό)[%]3 | |

|---|---|

| 1064nm | <0.5 |

| 532nm | <1.0 |

| 355nm | <1.5 |

● The laser adopts military standard, the whole cavity is made of aviation aluminum material, all the fittings are fixed locked and N2 sealed, the industry has high stability and resistance.

● Laser compact compact size,48V DC power supply, no need for additional power, convenient system integration and maintenance.

● Two new technologies have been added to the Centurion relative to the next-generation product, the Centurion: no headpulse energy problem and direct output square uniform spot, greatly improving laser energy stability and machining performance (cutting and welding without damaging the underlying material or causing explosive points).

● This laser belongs to DPSS 100Hz laser, which has high energy stability and can be adjusted with high precision, which is suitable for cutting and welding requirements of Array CF(COA) Cell and Module repair process.

● Optical module (including wavelength selective energy precision control precision adjustable slit mixed wave lighting source, etc.) suitable for LCD OLED precision repair.