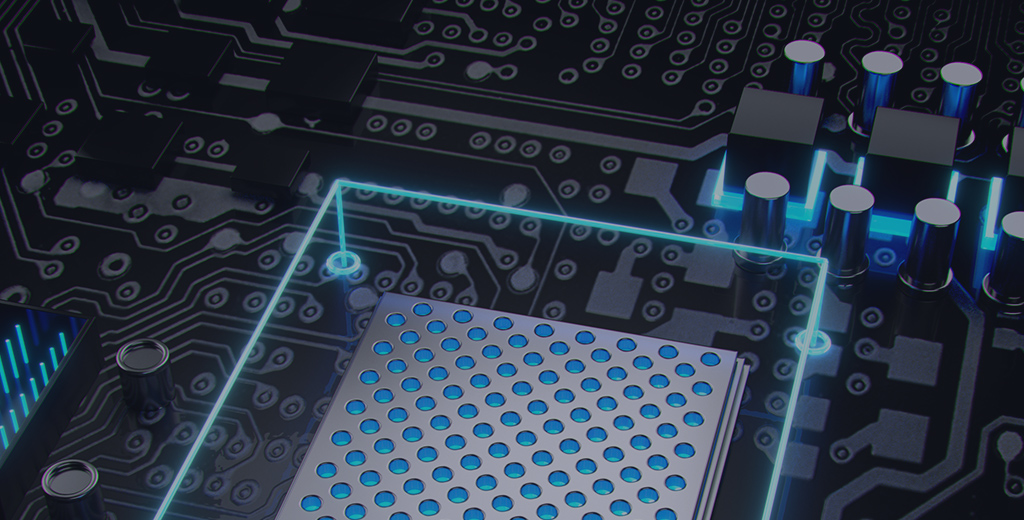

The new Chip Era

When the products of science and technology of the era are increasingly penetrating into people's future life, ecological industry is constantly derived, 5G, artificial intelligence, smart city, interconnection of everything, constant upgrading of advanced technologies and continuous iterative updating of products make future intelligent life more possible. As an intelligent carrier, chip has activated massive market demand. At the same time, due to global trade frictions, the domestic semiconductor industry is faced with the challenge of expanding the capacity of new chips and advanced manufacturing processes, and at the same time, it also faces great opportunities.

The application of advanced industrial technology

Wafer testing usually requires testing the electrical performance of the integrated circuit on the wafer to determine whether the integrated circuit is good or not. In the process of test, through the probe is used together with the test machine, the chips on the wafer function and electrical parameters of the performance test of the wafer pv films will be automatically transmitted by prober to test position, chip Pad points through the probe, special cable connection with testing machine function module, test machine on chip input signal, collection and output signal, judge the chip in the effectiveness of the function and performance under different working conditions. The test results are sent to the probe station through the communication interface, and the probe station marks the chip accordingly to form the wafer Map.

Black technology helps, wisdom sees the future

1. The external and shielded cavities are double-lumped to provide a vacuum environment with a limiting pressure of 10-4Pa for sample testing (when molecular pumps are used).

2. XYZ adjusting system of probe arm self-locking screw and cross roller guide rail structure, accurate probe positioning 10um, probe drift is better than ±60nm/30mins precision point needle; At the same time, the triaxial tube fixture is connected with the triaxial cable with high shielding function, and the leakage accuracy of the test is up to 50FA.

3. Air spring type support frame vibration proof system, effectively avoids the test influence brought by the slight low frequency band vibration.

4. The microscope adjusts the support freely and with its own adjusting seat, so that samples can be observed in any area. 20 times eyepiece and 0.8-5 times objective zoom ratio, achieving the sample magnification ratio of 16X-100x.

5. The coaxial circuit of refrigerant inhibits the early consumption of refrigerant, improves the refrigeration efficiency and reduces the consumption of refrigerant. At the same time, the refrigeration system regulates the precision needle valve, automatically controls the flow and temperature.